Imagine that your goal is to increase product sales. Specifically, increasing sell-through at retail. You’ll need signage, displays, promotional items, or other creative products that effectively communicate the essence of your brand.

Maybe you have a larger budget for the holidays—your highest annual revenue for the year—and you want to take your store windows to the next level.

A standard Google search will link you to zillions of possible ideas and suppliers. Sometimes the easy choice is to go to any first-page-result printer or fabricator with an existing product close to your specifications. But will you really get the best possible result, at the best price?

Unfortunately, you probably won’t.

Two not-so-secret secrets in the print, POP display fixtures, and promotional products industries:

- Suppliers base the products and services they offer on the specific equipment and people they have on hand.

- When your needs don’t align with what their machines and people can do, they’ll often sub out the project for trade work, but still tell you it’s all in house.

These realities mean that supplier recommendations—for everything from design to materials to assembly and installation specifics—will be based on a) which machines they own and expertise they employ; and/or b) who they know in the industry.

As a result, the solution you’re offered may not be the most durable, creative, timely, environmentally friendly, or affordable—in short, it might not hit the “sweet spot” for your project or your priorities.

Let’s take a deeper dive into this issue and investigate alternatives to get exactly what you need.

Feeding the Machine

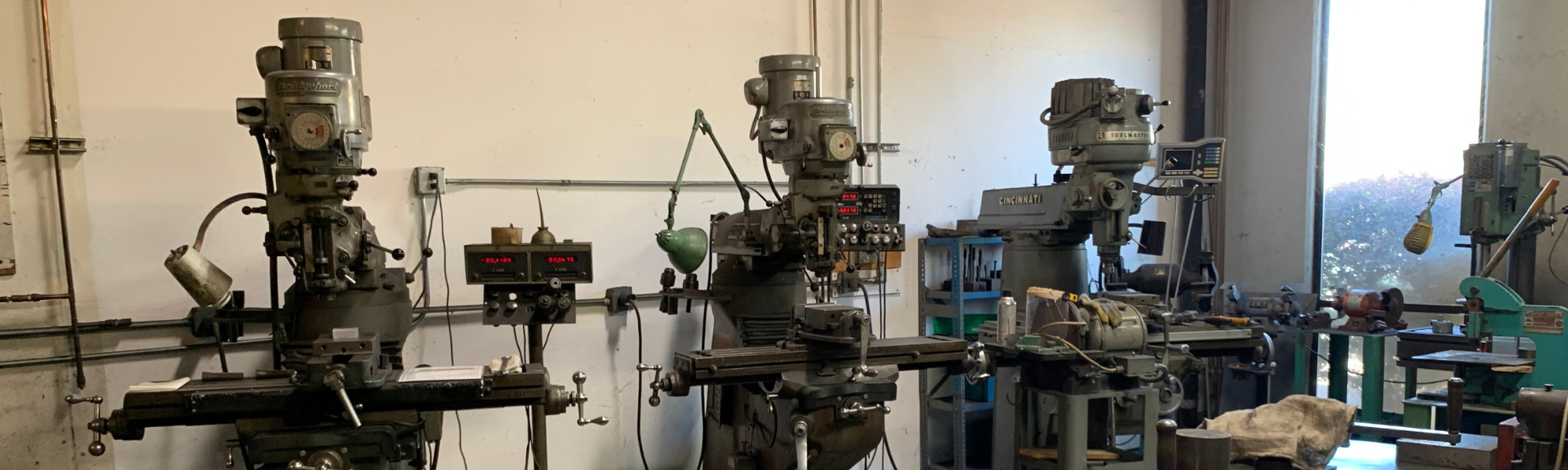

Things like wide-format printers are expensive. As in millions of dollars each.

Technology is also advancing rapidly. That means, today, new equipment is purchased more often than ever before. Redundancy is necessary to insure against breakdowns, so most suppliers buy multiple machines that can “do the same job.”

All told, we’re talking big money here. And because companies must be profitable, they strive to maximize the return on their huge investments—ideally, the machines are running non-stop.

A company with laser cutters will, therefore, tend to recommend constructing a display out of a material that their lasers can cut. A company with dollars sunk in CNC machines, on the other hand, will recommend that fabrication technique and the materials to make use of their equipment and expertise.

Have a tricked out 3D printer? It starts to look like the right tool for almost any job!

This situation has many implications. Let’s say your goal is to purchase a tabletop display to hold a graphic. A plastic display company may suggest an acrylic, heat-bent angled sign holder. A woodworker, in contrast, might suggest a wood base with a slit—at 5x the cost and 2x the lead time!

While there is no right or wrong, the best option depends on your specific need, which neither shop may actually meet.

A Hidden Middleman

What happens if you have a project that doesn’t feed the right machines? Many suppliers will still bid on the job, but then you are relying on them to serve as a middleman, outsourcing to and managing other shops.

How transparent and effective are they in this role? How hard will they (and can they) negotiate price on your behalf? Will you pay a large markup? Does this handoff introduce potential problems over project management coordination or quality control?

In these cases, you may end up with a half-measure solution, with a full-measure investment of your time and energy.

Or as the saying goes, your mileage may vary.

A Materials Agnostic Approach

None of the above sounds terribly client-centric, does it? But what’s the alternative?

At TGS Elevate, we call it a “materials agnostic approach.” By that, we mean recognizing that each project is unique and requires a tailor-made solution. What’s more, it means understanding that the client is in the best position to choose which option meets their needs.

With a materials agnostic approach, a supplier will typically engage with clients earlier in the process. They can serve as a partner in concept, design, and prototyping and take the project all the way through production and installation.

In other words, they can start with your idea, design and explore various avenues, and reach a result that checks all the boxes.

Why pursue a materials agnostic approach?

- When the machines aren’t driving the decisions, creativity is unleashed. Want a design that curves and bows, features engraved and painted text, and is made light, modular, and easily assembled for shipping to your outlets? With a materials agnostic approach, that’s a “yep, can do!”

- When the machines aren’t the primary consideration, the client’s priorities take center stage. For instance, many brands are increasing their sustainability and social justice aims. Such objectives affect the materials to be used, production locations, and more. A materials agnostic partner can present corresponding options.

- When company-owned machines aren’t a limitation, projects can be bid out to an array of pre-vetted, reliable partners, which maximizes price leverage and helps to stay within your budget.

The keys to making this model work are transparency, collaboration, and technology. With the right mindset and project management tools, a provider can work hand in hand with the client from concept to completion. End-to-end coordination and service enhance the experience and minimize the burden on your team.

Turn to TGS Elevate

If this sounds like an entirely different approach than the one you’re used to—well, you’re right!

The materials agnostic model is our response to the often unquestioned, “old school” way of doing things in our industry. And it’s fueled by innovation at every step.

Your creative products are meant to attract, engage, inspire, motivate, and captivate human audiences. Don’t allow decisions about them to be driven by the needs of the machines.

Want to explore how a materials agnostic approach can transform your creative capabilities and output? Check out our website at www.tgselevate.com